TC/American manufactures “patented track” rail in 5 different tee widths and thicknesses to provide you with the exact system components to meet your load conditions. Plus, TC/American manufactures a 2″ bolted rail design used primarily in commercial laundry monorail systems.

The backbone of any monorail or crane system is the rail. At TC/American Crane Company, we manufacture rails specifically designed to provide the maximum in strength, flexibility, and durability. Our rail uses high carbon-manganese steel tee sections which are rolled to close tolerances for maximum strength and long life while keeping weight to a minimum. These special alloy steel tee sections provide many years of dependable service, as compared to common structural steel beams which are mild steel and not precision made. TC/American Crane offers patented track in numerous standard rail configurations for a variety of applications up to 20-ton or more capacity.

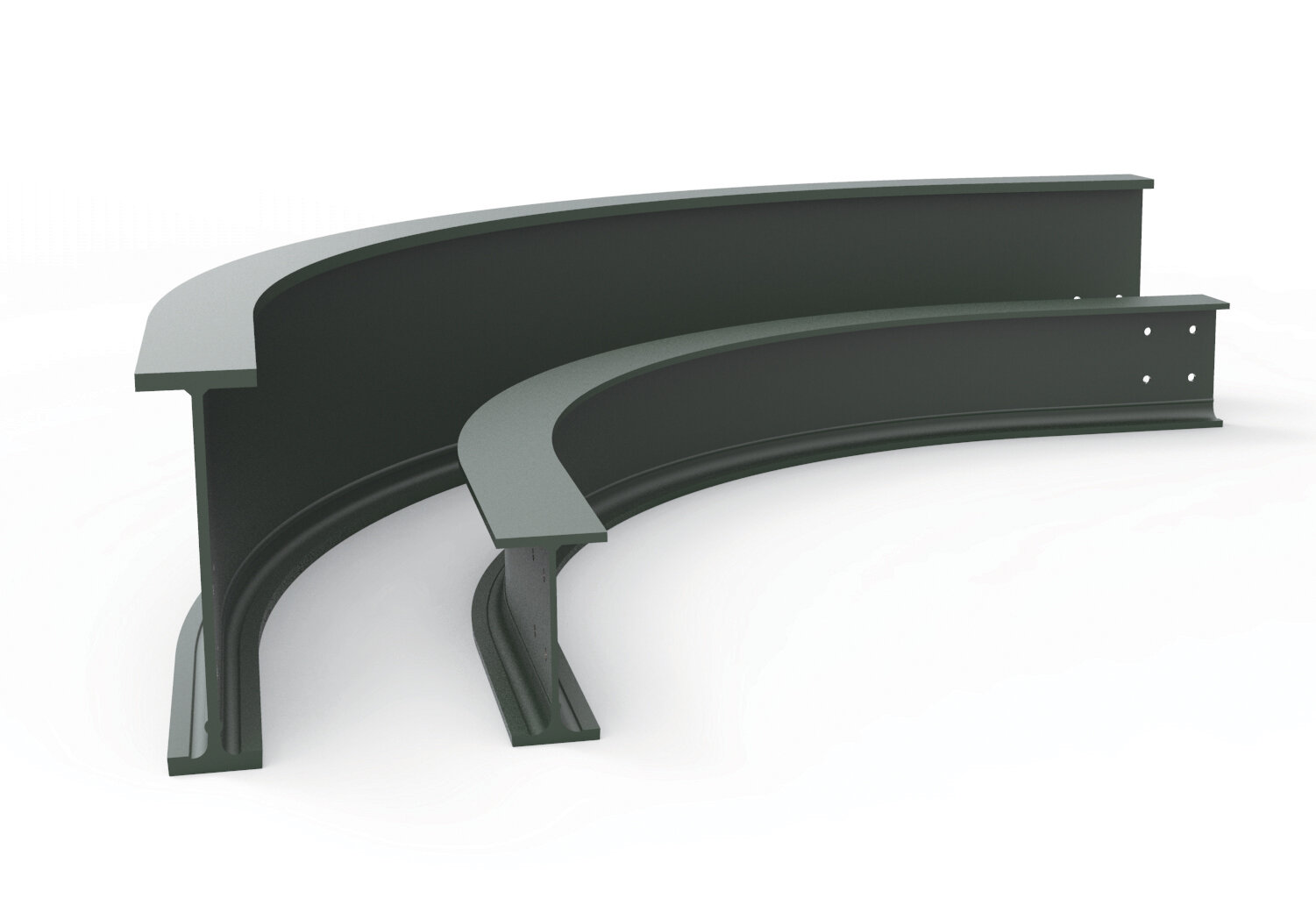

Curves

Curves are cold formed and available in all track series in radiuses starting at 24″.

Curves are formed from TC/American patented track rails. Standard curves and radii are available as well as curves that are formed to meet your exact needs. Monorail curves may be right hand, left hand, reverse (“S”) and be almost anything up to and including 360 degrees. Curve radii may be as tight as 14″ for non-electrified 200 Series or 40′ or greater on 325, 400 or 450 Series rail.

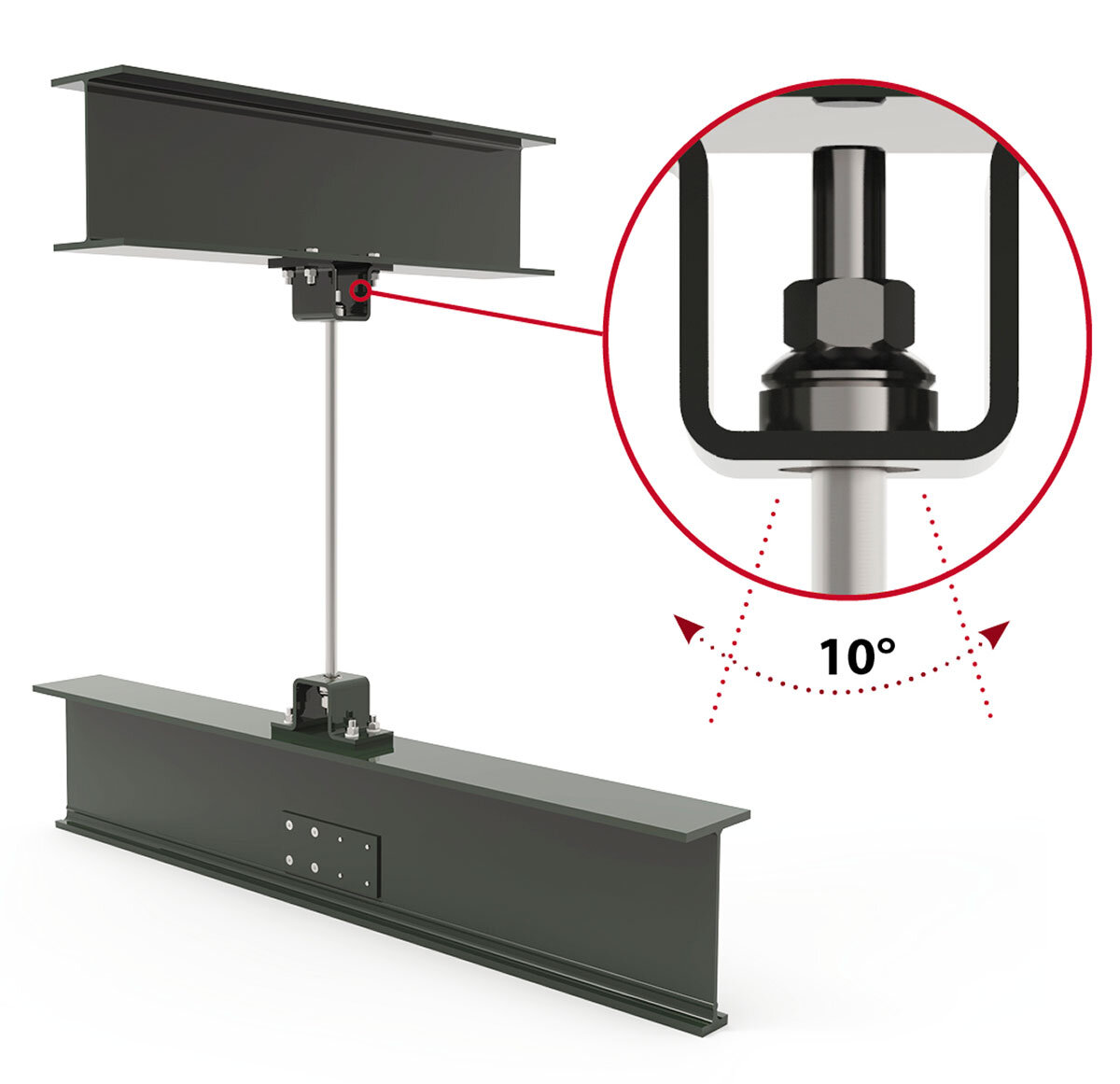

SUSPENSION ASSEMBLY

Our flexible suspension system may be bolted or clamped to support steel and is available in capacities up to 40,000 lbs.

Use of this system may reduce the number of sway braces needed as compared to an ordinary rigid hanger rod system. Spherical seats and washers areused to allow up to 5 degrees of movement from perpendicular; which may reduce installation time since it can accommodate some “out-of-level” conditions, without the need for additional shimming.

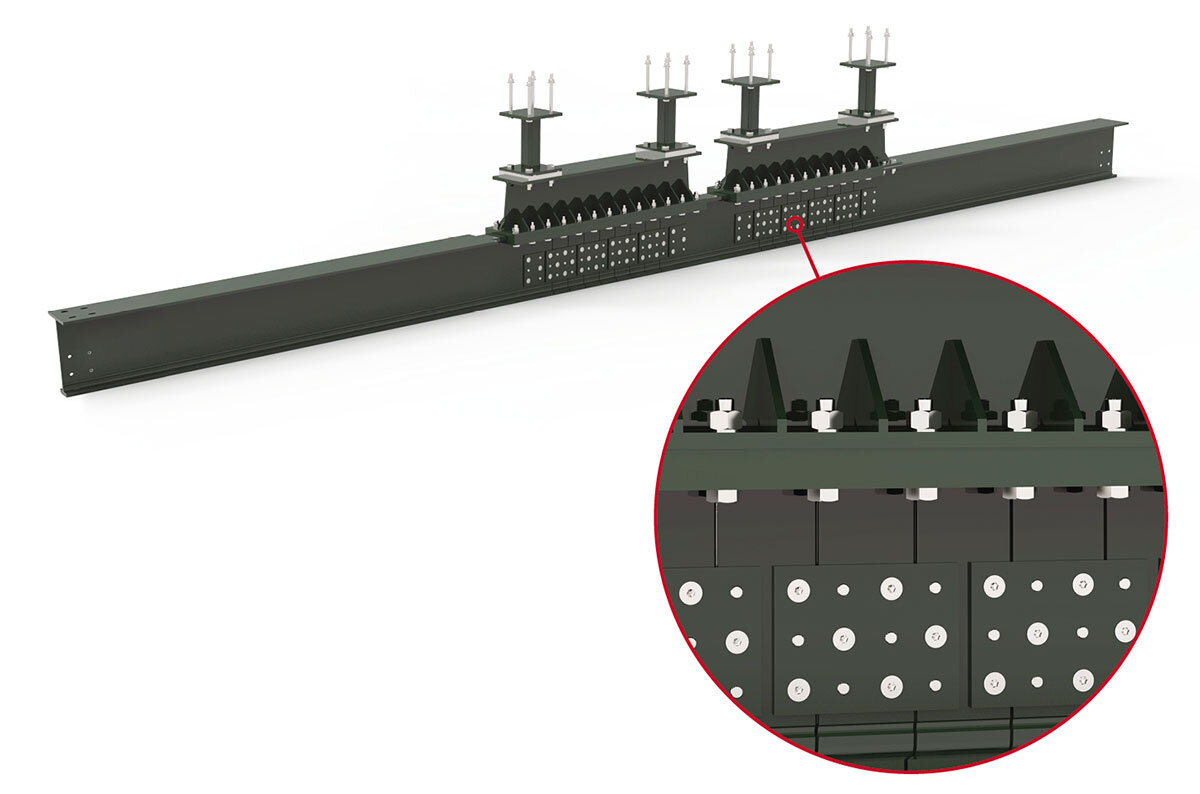

EXPANSION JOINT

Allows use of a monorail or runway across buildings expansion joint without compromising its ability to function.