SPANMASTER Work Station Cranes By TC/American Crane

TC/American is very proud to announce our new Enclosed Track Work Station Cranes. SPANMASTER Work Station Crane Systems are available in both freestanding and ceiling mounted designs. SPANMASTER Work Station Crane capacities range from 250 lbs to 4400 lbs. Stretching beyond our competitors, we designed our ergonomic enclosed track system to handle overall bridge lengths up to 38’6″. SPANMASTER bridges are designed for a 1′ overhang which provides a maximum crane bridge span of 36’6″. The final differentiating factor is the unique range of motion provided by SPANMASTER’S unique end truck design. TC/American’s patented articulating end truck design allows the crane to manipulate more like a jib crane when loaded at one end.

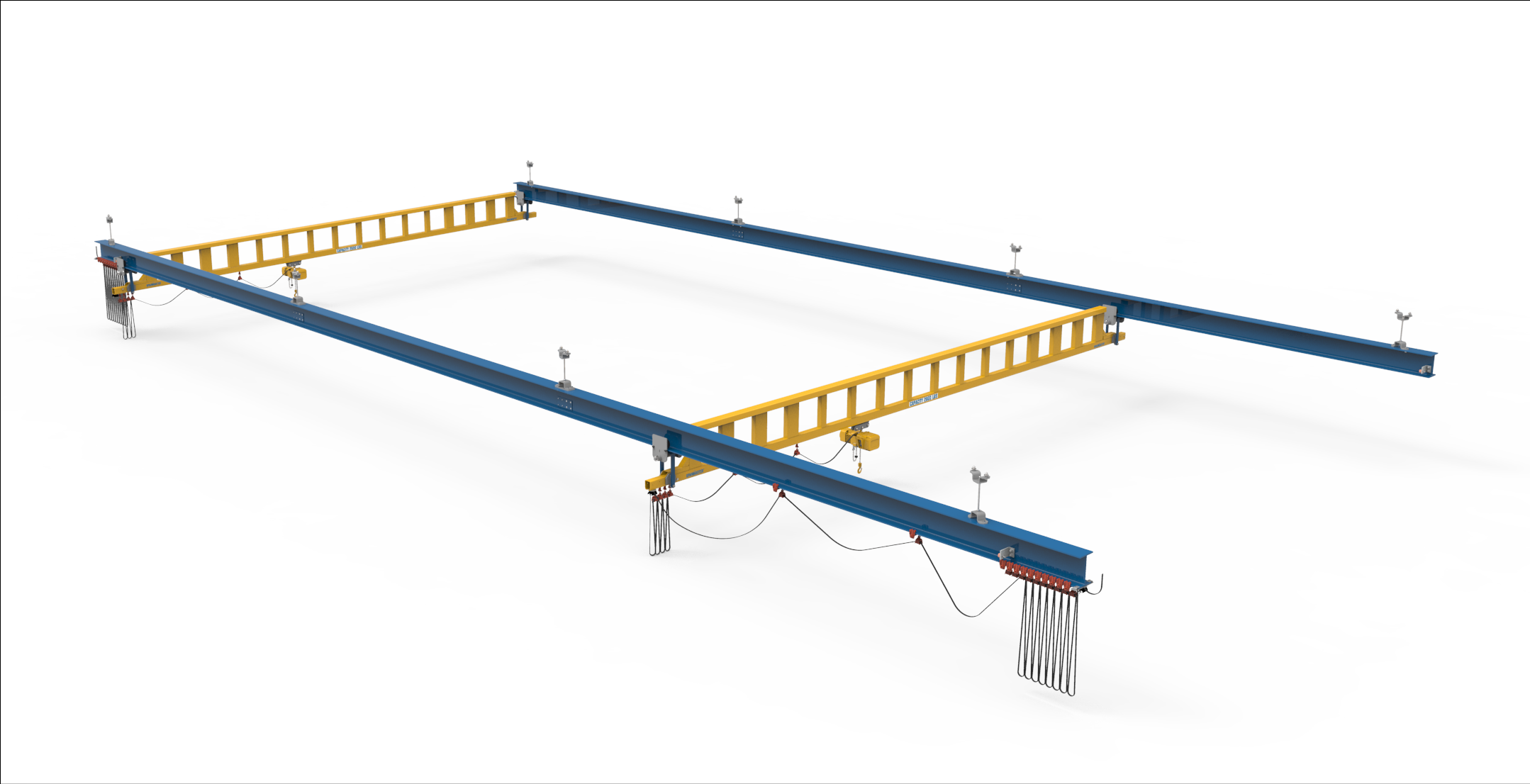

Ceiling Supported SPANMASTER Systems

Kits Include:

Enclosed Track Bridge With Articulating End Trucks

Hoist Trolley

Hanger Assemblies

Runway Beams With End Stops And Splice Assemblies (When Required)

Flat Cable Festoon Electrification For Runway And Bridge

Hardware

Installation And Operation Manual

Years Of Dependable Service

SPANMASTER Free Standing Kits

Kits Include:

Enclosed Track Bridge With Articulating End Trucks

Hoist Trolley

Free Standing Supports

Runway Beams With End Stops and Splice Assemblies (When Required)

Flat Cable Festoon Electrification For Runway And Bridge

Hardware

Installation And Operation Manual

Years Of Dependable Service

Advantages Of SPANMASTER Workstation Cranes

SPANMASTER Range of Motion

Our SPANMASTER Sytems use a fixed runway beam with an oscillating, articulating, and pivoting bridge. The bridge articulation is achieved by our Patented SPANMASTER end trucks. Our end trucks feature a unique ball pivot and u-hanger design which allows the bridge to manipulate similar to a jib crane. Through the lever-action created by the u-hanger lower pivots, operator effort to move the load is reduced significantly. With our unique end truck design we are seeing push/pull forces as low as 100:1

SPANMASTER Industry Leading End Approach

A major factor when deciding if a solution will work for a particular application is the crane bridge end approach. TC/American’s SPANMASTER Work Station Cranes remove that variable from the equation. SPANMASTER end trucks vary in overall length depending on the capacity and bridge span of the crane, but our largest end truck (4400 lb Capacity) comes in at an overall length of only 9.375″! This should make SPANMASTER your go-to solution when looking to maximize end approach.

SPANMASTER Non-Proprietary Runway Beams

When we were designing our new SPANMASTER Work Station Crane System, we wanted to create an easier and more cost effective solution for our customers. By utilizing a non-proprietary wide flange runway we are able to provide a large variety of benefits with choosing a SPANMASTER System:

More Cost Effective And Lower Freight Costs

Greater Design Flexibility With Multiple Bridges and Mixed Capacity Systems

Flexibility To Add A Work Station Crane To Your Existing Runway System

Offers Longer Support Centers Than Traditional Enclosed Track Runways